Services

At Inmecolsa, we offer advanced and customized solutions in plasma cutting, dome end forming, sheet rolling, and horizontal turning, tailored to the specific needs of various industries.

Plasma Cutting

Pumping

We offer a high-precision plasma cutting service, capable of cutting stainless steel sheets up to 4” thick. This service is ideal for handling a variety of thicknesses and types of stainless steel, allowing for precise and customized cuts according to client specifications.

This service is especially useful for:

- Tank Manufacturers: Ideal for manufacturing custom components or upgrading existing equipment.

- Metalworking, Food and Beverage, Pharmaceutical and Chemical Industries: Suitable for various applications, from the construction of machinery and equipment to the manufacturing of specific components for these sectors.

We offer a specialized dome end forming service using a 500-ton press. This equipment can shape concave ends and domes with a diameter of up to 4000 mm and a thickness of up to 1 inch.

This service is ideal for:

- Tank manufacturers requiring high quality, custom components.

- Maintenance departments in companies in the food, beverage, pharmaceutical and chemical industries that need to replace or update tank lids and bottoms in their facilities.

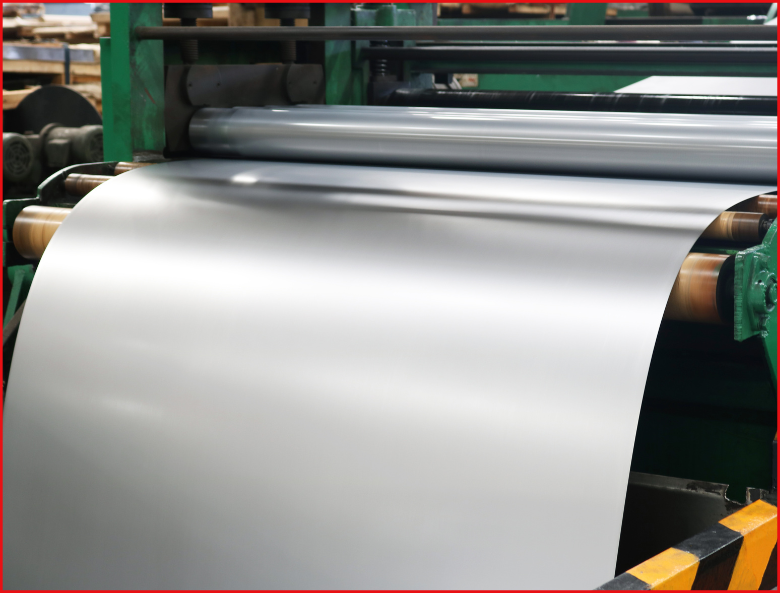

Steel Sheet Rolling

Horizontal Lathe

We offer a sheet rolling service specializing in the formation of cylinders for tank bodies and pipes. Our capabilities include rolling sheets up to 1800 mm wide and 4.5 mm thick, with a minimum diameter of 10 inches.

We have additional equipment that allows us to handle larger widths and thicknesses, adapting to the specific needs of our clients.

This service is ideal for:

- Tank and Pipe Manufacturers: Especially for those that require the production of large diameter cylinders.

- Food, Beverage, Pharmaceutical, Chemical and Petrochemical Industries: Suitable for the manufacture of equipment and components that require high precision and quality in the formation of cylinders.

We have a horizontal lathe with a capacity of 6500 mm between centers and a swing of up to 1800 mm, ideal for machining large flanges, discs, and shafts.

With this equipment, we can machine components up to 3400 mm in diameter, ensuring high precision and quality in each part.

This service is especially useful for:

- Tank Manufacturers: For the manufacture of customized and large components.

- Chemical and Petrochemical Industry: Ideal for the production of special equipment and parts that require precision and durability.